Introduction

In this install we will go over the installation of the OS Giken Super Lock LSD on a Subaru BRZ and the removal of the oem differential. This how-to is one of the few installs that will cover both removals and installs of the parts in question.

Tools

No tools specified.

Parts

-

-

To start things off we need to get some things out of the way, specially the exhaust.

-

Remove Exhaust. The Exhaust will get in the way of removing the LSD housing so it must go.

-

Please refer to our previous exhaust removal write up in order to observe the process

-

-

-

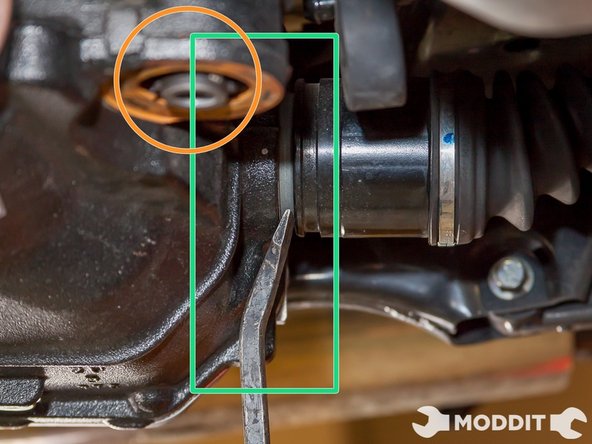

The next step is to Drain the Oil

-

Remove the fill bolt with a 10mm allen key so it splashes less when you remove the bottom fill bolt to drain the LSD oil

-

Remove the drain bolt with the 10mm allen as well.

-

Drain the differential oil to a drain pan and clean off any residue on the bolts. Specially the lower one as it has the magnet that collects any metal shards.

-

Put the drain plug and fill plug back in. Before doing so however, make sure you have the appropriate crush washer to prevent any sort of threading.

-

-

-

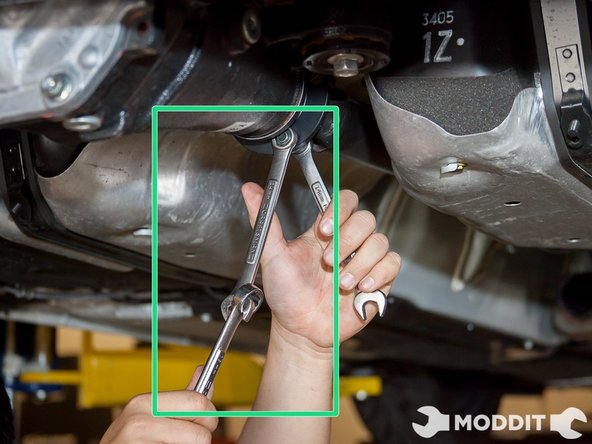

Loosen two bolts holding up the center of the driveshaft. We would recommend not removing them.

-

If you remove the driveshaft from the tranny, you will need to refill the fluid.

-

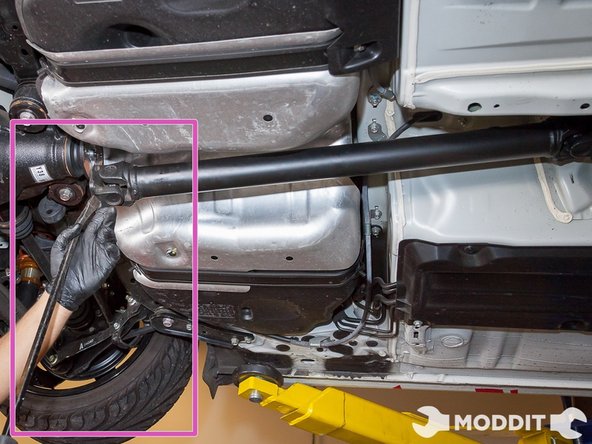

Pry the rear of the driveshaft off the carrier housing using a pry bar.

-

Let the driveshaft hang. Be careful not to hit your head while working on the differential.

-

-

-

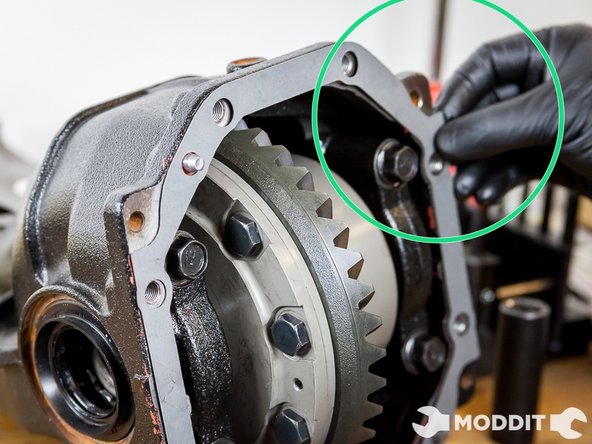

Next, Pry the axles off the differential. You want to do this now as it is easier when the front ear bolts and rear bushing bolts are in. Make sure to pry it at the correct location as noted in the picture. If you pry the shield it will break.

-

It should pop out about 1/2 an inch if you're successful. You will not be able to remove them completely at this point however.

-

Again we did this while the differential was secure so when one applies force to the axles the Differential does not move and counteract your attempts to remove it.

-

-

-

Our next step is to remove the Rear Bushing bolts. Remove the 2 17mm rear bolts holding up the differential cover on the left side bushing.

-

Then proceed to loosen the right bolt holding the rear differential cover bushing. Use a 17mm 1/2 deep socket if you have one. Because many people will have different exhausts use your best judgement on socket selection to maneuver apprpriately

-

At this point we recommend you have someone to help your support the differential housing. A Transmission jack would help as well.

-

-

-

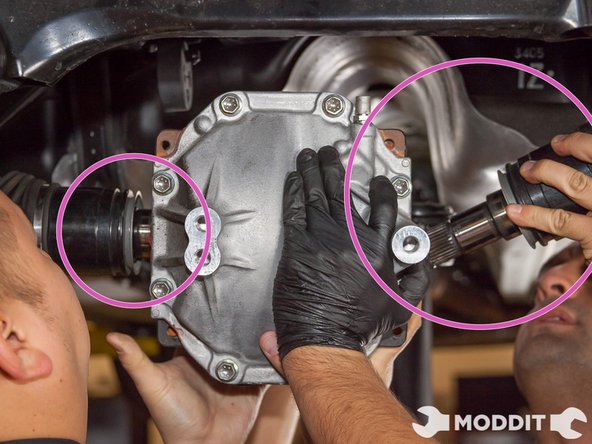

The Last bolts we need to remove are the two frontal Differential "Ear" Bolts. This is where your friends or tranny jack come in

-

Proceed to remove the left bolt holding up the differential ear.

-

Then move on to loosen the right bolt holding up the differential ear.

-

Once the last bolt is out carefully guide the Differential case down and proceed to remove the shorter axle first. This would be the unit closes to the passenger side. Then remove the driver side.

-

-

-

After you have the differential case out, set it down somewhere when you can easily work on it. A sturdy table top works great

-

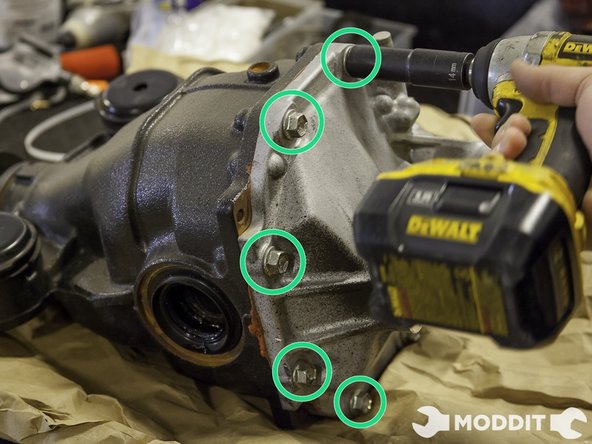

Proceed to remove all the 14mm Bolts securing the rear differential cover with a 14 mm socket.

-

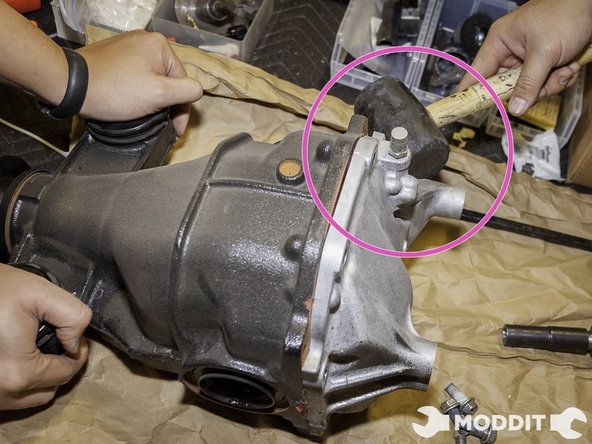

Once they are all out get a small hammer gently dislodge the rear cover until it is completely off. A good spot to tap it from would be the Right Bushing Bolt receiver section. This allowed us to easily pop the cover off.

-

-

-

After the cover is removed make sure to clean the surrounding, mating area with a screwdriver or knife blade. Be extremely careful not to damage this surface.

-

You will see that a lot of silicone RTV will come off and could potentially mess with your re-installation.

-

We decided to use a brand new prototype LSD Gasket produced by DIF and exclusively offered by FR Sport. This gasket ensures better sealing than simply using silicone RTV. After one is done working with the pumpkin internals aka the differential, its is recommended to use this gasket or the RTV as a last resort.

-

-

-

The next few steps will lead you through the removal of the actual LSD mechanism inside the pumpkin

-

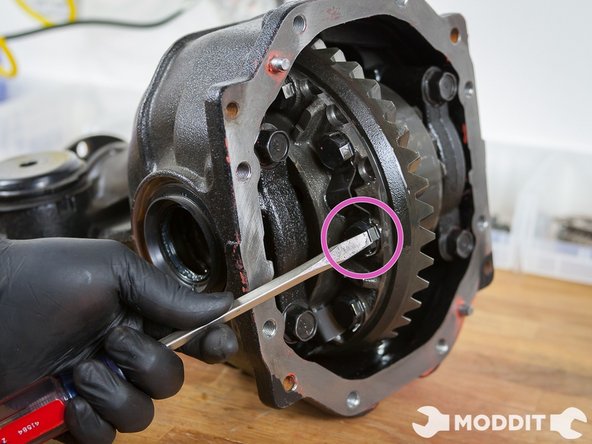

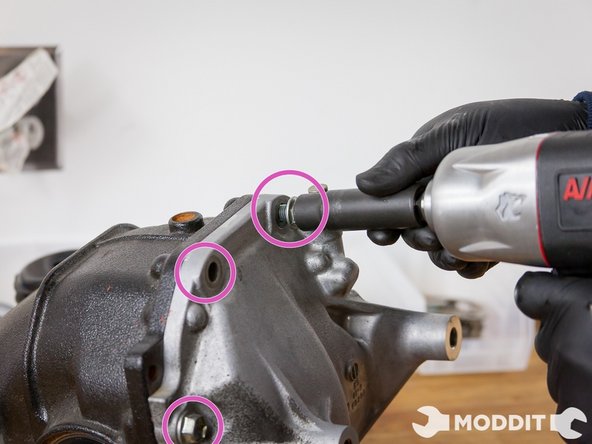

Begin by hammering down, with the aid of a srewdriver, the locking tabs that secure the bolts fastening the LSD Ring

-

Try to use various angles to achieve flattening all the locking tabs just enough to let you use your tool of choice. We were using an extended 17mm Socket and impact gun for quick removal. You will not be using these locking tabs again.

-

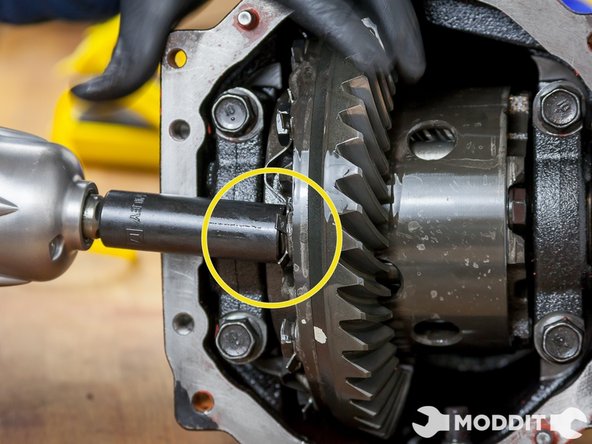

After all the locking tabs have been flattened, proceed to use your tool to remove the bolts securing the LSD Ring. We do this now in order to save us the trouble of having to do this when outside, which would make it a lot harder.

-

-

-

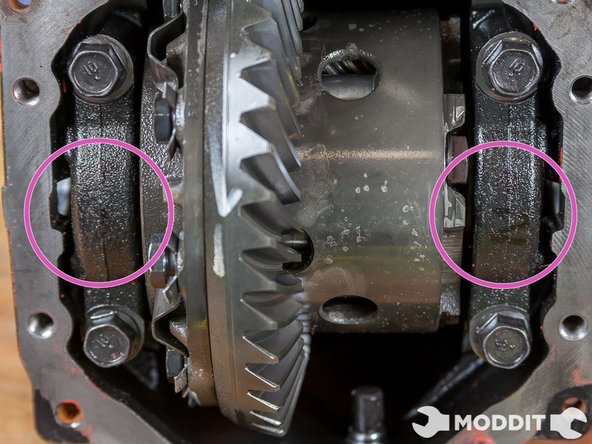

You will then want to mark the two metal retainers securing the Bearing Holder and Bearing in order to maintain a proper re-installation. They are also side specific and is why we marked them

-

Here you can see we just named them side 1 and side 2.

-

After you have marked them using the same 17mm socket proceed to remove both of the metal retainers by removing the 4 bolts and place them aside always knowing which is which.

-

-

-

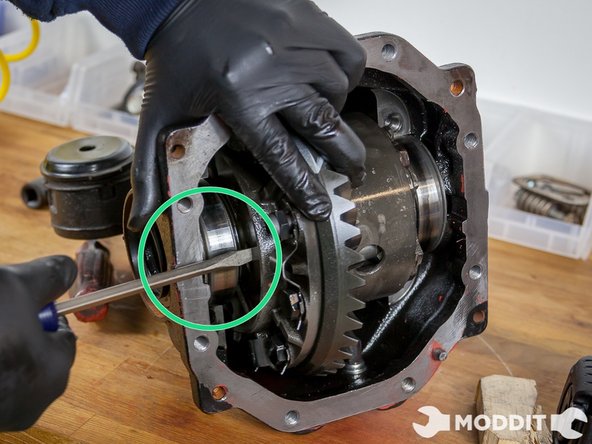

Once the metal side retainers are out of the way you are clear to start removing the actual Differential Mechanism. Be prepared for a fight as this step requires some force.

-

Using either a strong flat-head screwdriver or crow bar find strategic points to tap out the diff'. What you could do is screw back some on some of the bolts used to secure the LSD Ring and use them as leverage. Simply tap and use force, without overdoing it.

-

As the Differential starts coming out, better leverage points will appear and start using those to remove the mechanism.

-

-

-

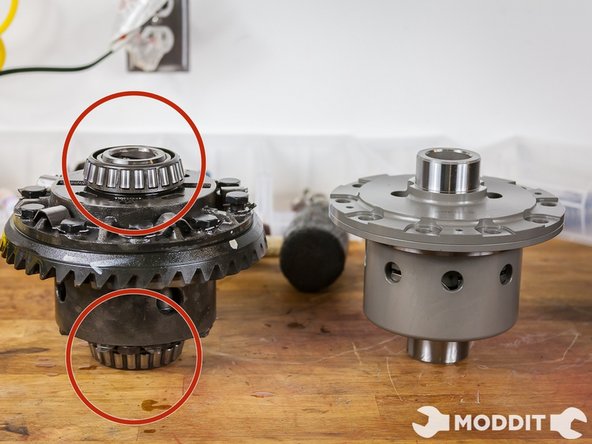

Once you have the LSD out it is time to prep for re-installation, using new parts and borrowing some from the oem LSD.

-

In theory it is possible to re-use the bearings of the outgoing lsd but you risk damaging or warping the bearings and so it is a better idea to source new ones from either Toyota or Subaru.

-

The Part number for these bearings is 9036650001 from Subaru.

-

You will have to press them on or have someone press them on for you. When you purchase the said part number above you get one bearing and one holding metal sleeve which means you have to buy a quantity of two of the part number above.

-

-

-

The one item you will have to swap over, unless you're converting your drive ratio, is the LSD Ring. It doesn't matter what order you do this or the bearing.

-

Begin by removing the bolts you screwed back on to help you remove the Diff' from the pumpkin. Once all out you can proceed to the next step.

-

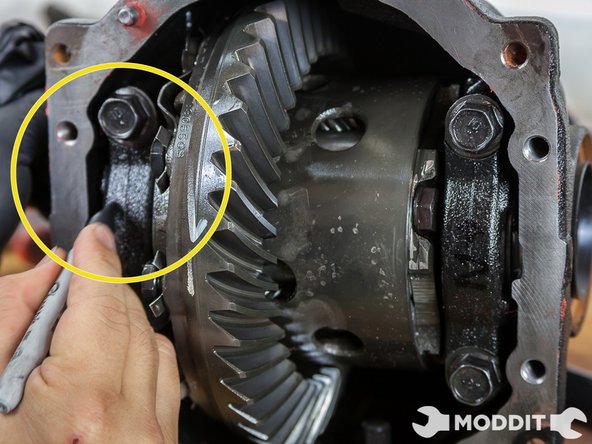

Using a combination of flat-head screwdriver, crow bar, and mallet begin taping out the ring.

-

It will be difficult to budge initially but once it starts moving, it will be easier to tap out. We used an an angled flat-head screwdriver for the last push. Once out proceed to bolt the ring to the new LSD, in this case we were installing an OS Giken Super Lock unit.

-

-

-

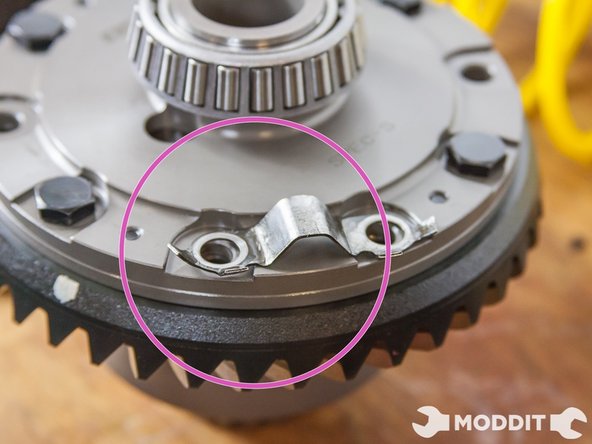

Before bolting up the OEM LSD Ring to the OS Giken Diff' make sure to coat them with some Loctite Thread Locker.

-

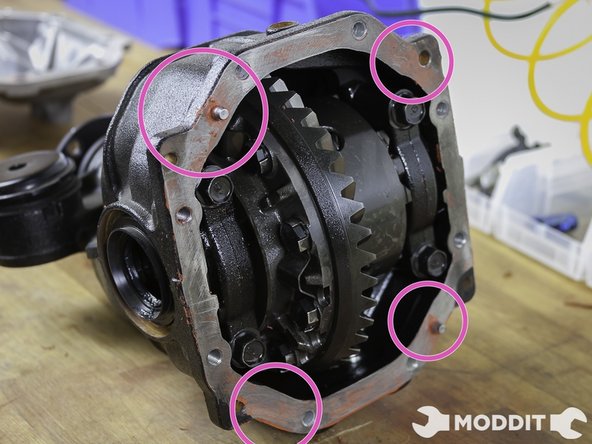

The reason being that we will not be able to re-use the thread locking tabs found in the OEM LSD. As you can see in the image, they do not clear the construciton of our OS Giken LSD. It is common knowledge however that they are not needed and one would be ok simply using the Loctite Thread Locking compound.

-

After all the bolts are coated with Thread Locker continue securing the rest of the bolts to the LSD Ring. Once all the bolts are in you will have to then tighten them at a temporary torque level. We used about 41 lbs of torques to tighten the ring before we put the whole differential back in.

-

-

-

After you have placed the LSD ring onto the Differential. It is now time to work on putting it back inside of the pumpkin

-

This part is extremely tricky as you will have to hold the bearing covers in place as the differential goes inside of the pumpkin. They will try to move a lot so do your best to keep them in place as the unit goes in.

-

Making sure that everything goes in straight is very important. The unit needs to be straight and the bearing covers need to be in place as it is sliding inward.

-

Once you verify that the differential is going in straight use a mallet and small piece for wood to continue taping it into place. You want to steer clear of metal on metal contact as it could warp the mechanism. Having a partner hold the pumpkin as you try to massage it back in is extremely helpful.

-

-

-

After you have succeed in properly placing the differential inside the pumpkin, it is then time to bolt on the "Bearing Holder Brackets". These are the black brackets located to the sides of the differential. Remember to bolt them on the correct side from which you unbolted them.

-

Also at this point you will continue to tighten down the LSD ring all the way up to factory torque levels. The goal is to get it as tight as the factory FSM recommends. Traditionally torque specs for an LSD ring range between 95 to 100 Lbs of torques.

-

At some point doing this becomes very hard so with the help of a friend have him or her place a metal screwdriver through the pinion wheel (the part that connects to the driveshaft) and use that leverage to tighten the LSD ring all the way up to the desired torque specs. Once finished you are ready to perform some final measurements.

-

-

-

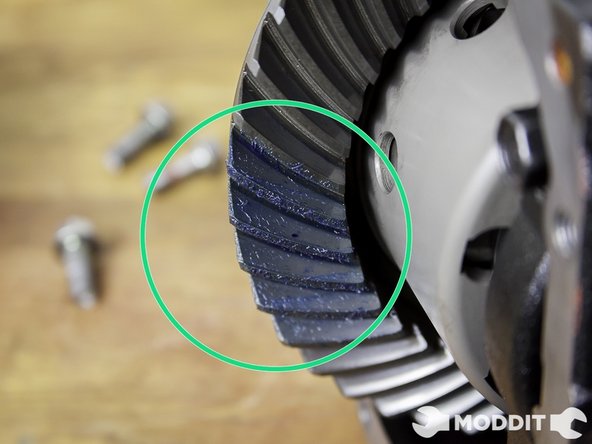

The next few steps are recommended to be done by a professional or at the very least someone with the appropriate tools to measure the backlash, or amount of play before the differential gear starts to contact the Pinion Gear and the contact pattern on the same differential ring and pinion gear.

-

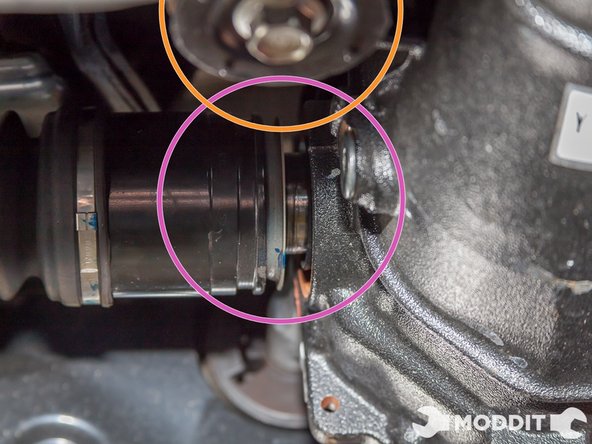

Here we painted on some Blue Loctite Marking fluid in order to inspect the engagement of the diff ring with the pinion gear.

-

After rotating it a few times one can see the contact surface and evaluate the pattern. Here you will be able to see just how off the contact is and whether or not you will need to re-install the differential again.

-

Using a dial indicator, position it so that you are able to measure the play between the differential ring and the Pinion gear. Use the Subaru FSM to verify the correct threshold of this effect. Technically you do not want the pinion and diff' ring to suffer too much shock or be too tight that it wears down both gears.

-

After this technical step is completed continue to the next step.

-

-

-

After all business with the internals of the pumpkin are set, begin buttoning up the rear cover of the unit.

-

Place the DIF gasket over the surface that will be mated to the differential cover. Again if you do not have access to the gasket, Red RTV will do the trick. Make sure you place it on correctly as well.

-

Once the gasket has been set, proceed with tightening the 8 differential cover bolts. These simply have to be fastened securely and not ridiculously over tightened.

-

Inspect the rear cover and make sure everything is securely sealed.

-

-

-

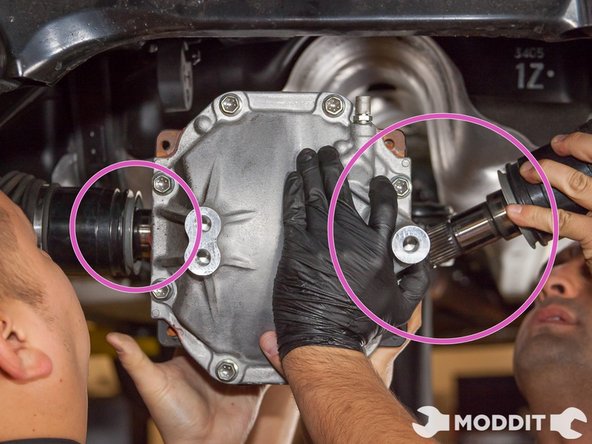

Re-installation is pretty straight forward and resembles the removal closely. You want to insert the driver's side axles into the pumpkin first and then follow by inserting the passenger's side next.

-

As you raise the differential pumpkin bolt the back of the differential cover and the two front differential ears to the rear sub-frame at the corresponding spots. Finally bolt the drive shaft to the pinion gear at the front of the pumpkin.

-

Using a soft mallet make sure your axles go in enough to engage and seal the area originally removed from. In the picture here you can see just how close they have to be to the pumpkin.

-

If you disconnected anything else in the process of removing your pumpkin bolt that up as well and you should be all set.

-

The OS Giken Super Lock Differential we installed did not need break in but yours might. Please follow the appropriate break in procedures for your LSD and enjoy your upgraded traction.

-

Cancel: I did not complete this guide.

3 other people completed this guide.